Read All About it: Franke x LiSEC

Read All About it: Franke x LiSEC

For this month’s blog post we are switching it up a bit and bringing you a customer story courtesy of our HQ in Germany. They have worked closely with this brand for years supplying them with our high-quality linear products.

A customer story courtesy of Franke GmbH..

For this month’s blog post we are switching it up a bit and bringing you a customer story courtesy of our HQ in Germany. They have worked closely with this brand for years supplying them with our high-quality linear guides.

We wanted to share a brand story with you as understanding what we do and who our customers are isn’t the easiest thing to wrap your head around. and we don’t want anyone missing out on upgrading their applications. Or have reoccurring challenges with their equipment.

So, let’s get into it…

Who are LiSEC?

Well, LiSEC are the world leader in flat glass processing, a company based over in Austria. They found their solution for their highly skilled machines by utilising our Linear guides.

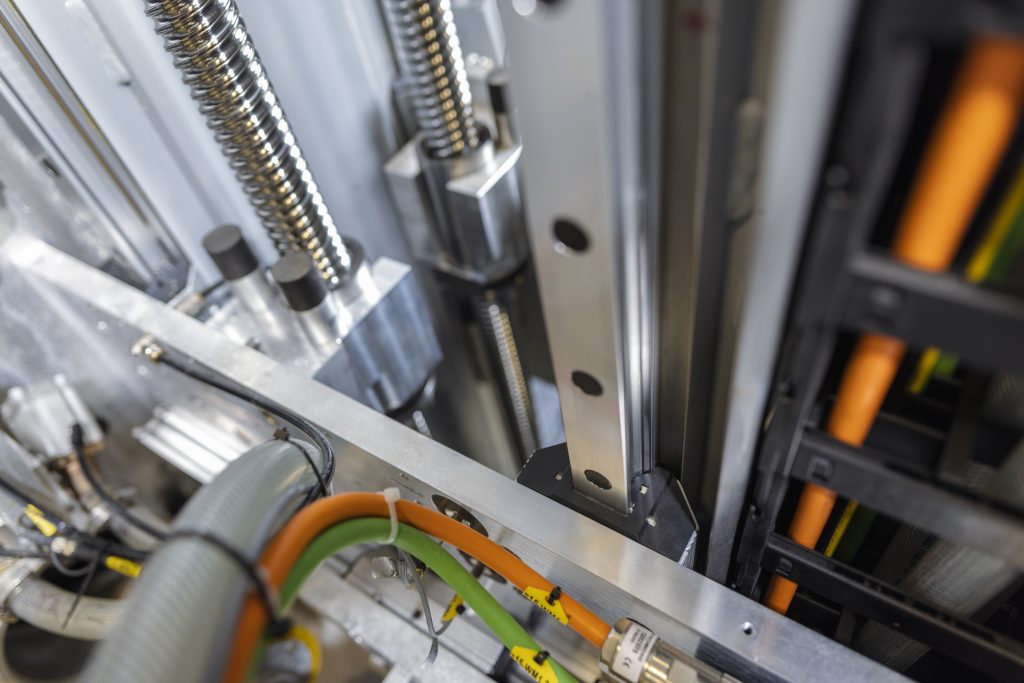

During operation, the machine components are exposed to an abrasive mixture of cleaning water and glass dust. But thanks to our unique linear guide design, incorporating sealed rollers, corrosion-resistant housings and components, these linear guides can withstand the toughest conditions.

LiSEC’s machines, software, and complete system solutions are used for the production of insulated glass. LiSEC has been using our linear solutions in their machines since 2017. So, they’re very valued customers!

Moritz Geyrhofer is the Lead Buyer at LiSEC, when asked about his biggest challenge he responded.

“The availability of supplier products.” His experience with Franke‘s reliability has been excellent and a significant reason why LiSEC relies on us.

Let’s talk some more about our linear guides…

So, to be specific the linear guides used in LiSEC’s machines are Corrosion-resistant FDC-35 Franke aluminium linear guides with stainless steel raceways.

They “fulfil essential functions for our machines,” says Geyrhofer.

They are used in edge processing and finishing, guide grinding or milling tools, and in numerous machine types to precisely position the processed glass sheets.

“At all costs we must avoid the production line coming to a standstill, because that would mean enormous losses in no time at all.”

Furthermore the linear guides are exposed to washing water and glass dust. Our unique linear guide design protects against corrosion, the FDC 35 model are made of stainless steel or aluminium.

The glass debris is removed from the raceways with wipers during each movement, so it does not accumulate on the rails or in the guides. The wheels of the guides are enclosed, which prevents dirt, dust or debris from affecting the function of the needle bearings.

So, Clogging is impossible and the wheels are also lubricated for life – making them maintenance-free.

Why do LiSEC choose Franke linear guides?

Good question, LiSEC’s central promise to its customers is productivity, therefore the quality of a supplier’s products is also very important.

“We have to avoid the production line coming to a standstill at all costs, because that would mean enormous losses in no time,”

He therefore appreciates the great quality of Franke’s linear guides.

“They have always remained stable over the years. It’s no use for us if a supplier makes an effort at the beginning and then the quality drops”

“When we turn to Franke for new developments or enhancements, we experience a very fast response and receive expert advice.”

Profile of the used Franke linear guides:

- Corrosion-resistant Franke linear guides type FDC 35

- Advantages used: resistant, durable, maintenance-free