Build Your Own Bearing: Why Custom Solutions Give Engineers an Edge…

When off-the-shelf components don’t quite fit the brief, engineers need more than a product… they need a partner. At Franke Bearings UK, we make it possible to build your own bearing, designed specifically for your application, your constraints, and your performance goals.

Whether you’re designing for automation, medical devices, aerospace, or defence systems, standard bearing solutions often limit innovation. They can add unnecessary bulk, weight, or friction, compromises that can reduce overall system performance. Our wire race bearing technology flips the script.

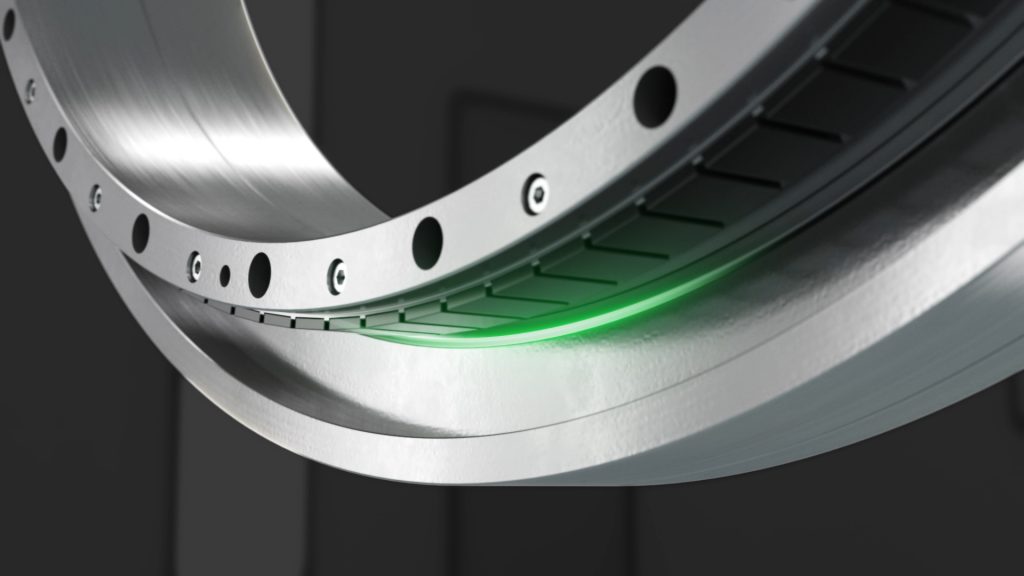

Unlike traditional bearings, Franke’s system allows the raceways to be embedded directly into custom housings made from aluminium, carbon fibre, or even 3D-printed materials. This approach opens the door to lightweight, compact, and load-optimised designs that fit seamlessly into your product.

Here is how the process works:

Tell us about your application.

We design a solution.

You get a bearing that works around your product, not the other way around.

This “build your own bearing” approach is ideal for compact robots, mobile imaging systems, radar platforms, and any application requiring precise motion in limited space. You’re not locked into standard dimensions, you control the geometry, preload, seal type, and more.

And if you’re using linear guide rail systems or direct drive motors, we can integrate those technologies too, creating a complete, performance-matched motion system.

Why engineers choose Franke:

-

Tailored support from concept to production

-

Free CAD downloads and design consultation

-

Materials and tolerances matched to your real-world demands

-

Scalable from prototype to full production

When performance, size, and innovation matter, custom bearings aren’t a luxury, they’re a necessity.