Linear Modules

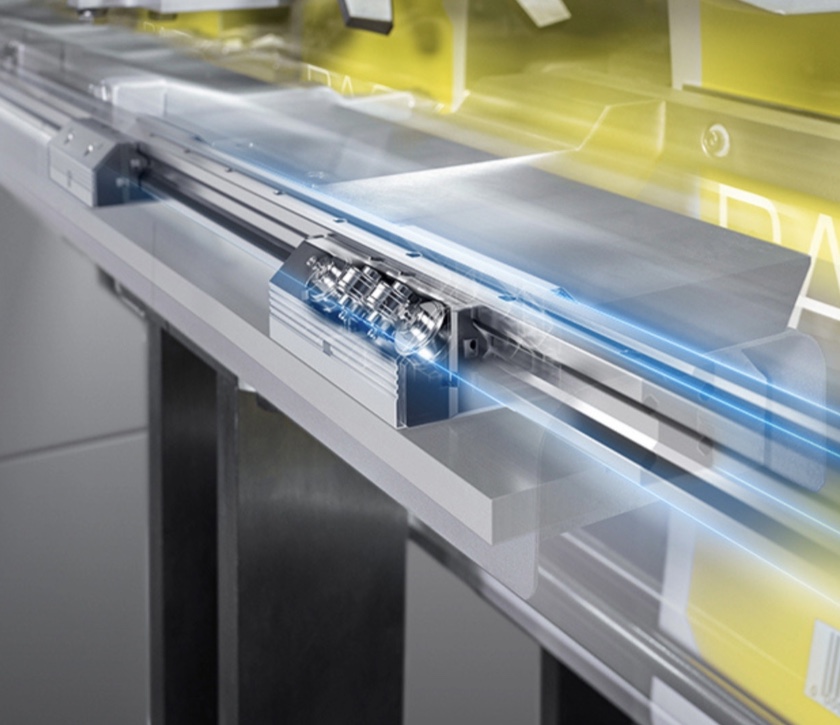

Franke Linear Systems are based on the tried and tested Franke principle of 4-point contact. The patented system of Guided Rollers and Franke’s guiding rail, moves the rollers and raceways smoothly and seamlessly. Franke’s aluminium linear guiding rail is perfectly suited for applications where highly dynamic movements needs lightweight design. Due to the outstanding functionality of 4-point contact and modular construction allows us to individually modify each Linear Systems to deliver precisely what your application needs.

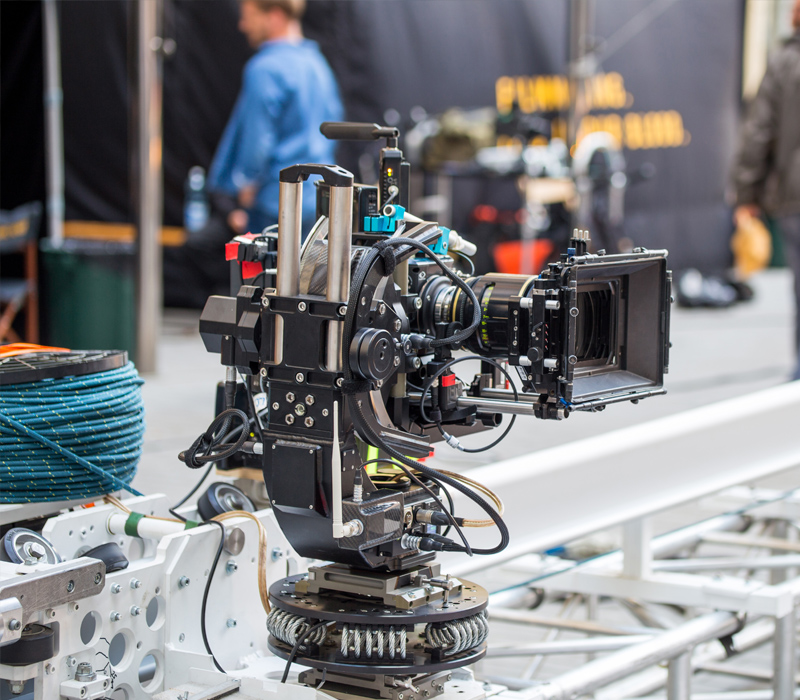

Franke Linear modules are offered with ballscrew or belt drive with strokes from 100mm to 7 metres. Available from stock & built to order on short lead times.

Download our linear module and guiding rail whitepaper below…

Low Weight – High Load

The design principle of our Linear Systems makes them highly dynamic, quiet and maintenance-free. Wire raceways made of steel or non-corrosive steel, integrated into the aluminium body of a Franke’s guiding rail ensure a high resilience and load capacity. Our guding rails are industry known and desinged to make an impact.

Franke Linear Systems can be modified individually to suit customer needs, thanks to their modular structure. You will always receive a solution that is ideally tailored to match your specific applications due to the use of various rail profiles and roller shoes, special cassettes, variable track widths or an integrated direct drive.

Profile Table

| Profile Names | Characteristics | Stroke Lengths |

|---|---|---|

| FTB |

|

|

Advantages

Highly dynamic, fast and quiet, enabling accuracy along the entire line.

Principle

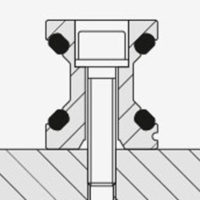

4 Point ContactPrinciple

Outstanding functionality due to the tried and tested 4-point contact. Wire raceways made of steel or non-corrosive steel inserted into the aluminium body ensure high resilience and load capacity. Allowing accuracy along the entire line.Maintenance

Lifetime LubricatedMaintenance

Franke Linear guides comes with lifetime lubrication ensuring the guide runs evenly, quietly and cleanly. Central lubrication on Franke linear cassettes allows for high service life and mileage, in turn reducing downtime and maintenance.

Lightweight

Aluminium DesignLightweight

Integrated raceways made of steel or non-corrosive steel take high loads from all directions. Franke Aluminium linear systems are perfectly suited for applications where highly dynamic movements and light weight design are paramount.