FAQ’s – Linear Bearings

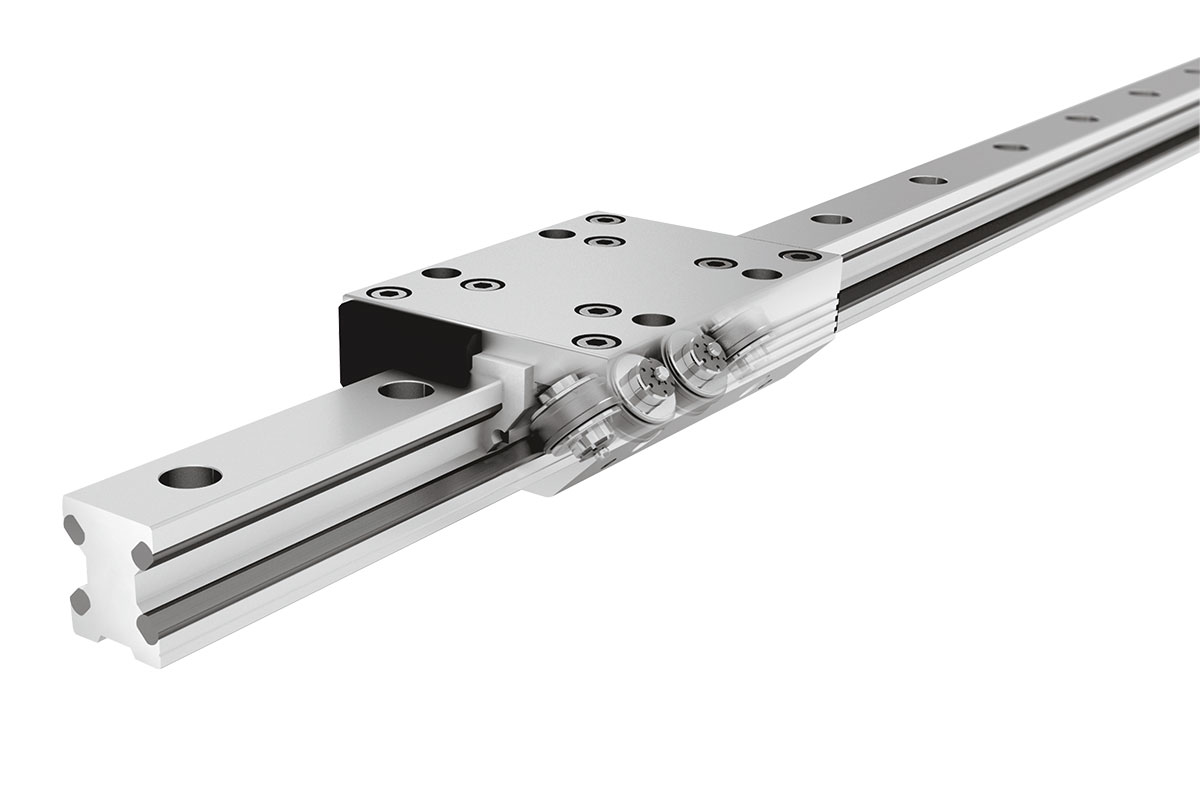

Franke linear guides are factory set free from clearance.

If the respective load situation requires this, the clearance can be subsequently adjusted by using an integrated threading pin.

- Wiper (Standard)

- Metal Wiper

- Bellow

With Franke linear systems, travel speed up to 10 m/s and accelerations up to 40m/s² can be reached.

| Size 12-20 [mm] | Size 25-45 [mm] | |

| Max. tolerance for parallel run | 0,03/m | 0,05/m |

| Max. evenness of screw-on surface | 0,05/m | 0,10/m |

Franke Linear Systems are low-maintenance and have factory-fitted lifetime lubrication.

Relubrication is not necessary, apart from the ball screw. Relubrication may be necessary – depending on the use – resulting from leakage of grease via the spindle shaft.

We recommend relubrication with approximately 1 – 2 g grease in intervals of approximately 700 operating hours.

If necessary you should clean the insides and the guide tracks and coat them with grease.

The slide resistance depends on how long the linear guide is running in certain sections.

The corresponding travel speed is also important.

For a precise definition of the slide resistance please contact our technical support.

This can be achieved by a rework at the bottom of the cassette.

Please get in contact with our technical support for more detailed information.

The following parameters are required to correctly design the guides:

- Selection of arrangement

- All prevalent forces/moments (dynamic/static)

- Load type (resting, expanding, alternating)

- Ambient influences (e.g. temperature, moisture) or special operating conditions (e.g. clean room, vacuum)

- Travel speed and acceleration

- Stroke length

- Target service life in km

All prevailing forces and moments must be within the specified limits.

In most cases, the dimensions and the drilling pattern are similar or even identical. However, the load ratings can differ.

For an examination of the compatibility, please send the name of the manufacturer as well as the designation and a drawing

of the rail to our technical support.

The dimensions of the rail will then be compared to our cassettes.

We will be pleased to prepare a lifetime calculation for you.