LEL Specification

LEL – Ground raceway

Product type

- 4 race rings with ground raceways

- Plastic ball cage with retained balls

- Franke bearing elements in type LEL meet high standards in terms of runnability and accuracy. Their hardened and CNC-ground raceways, along with the ideal geometric adjustment of ball and raceway radius, lend them outstanding bearing properties. Bearing elements in the LEL type permit the greatest possible freedom of bearing design. The standard mounting space is between 5.9 mm and 20.9 mm. Race ring thickness of up to 20 mm and bearing sizes up to 50 mm are possible to meet special requirements.

Characteristics

- Maximum possible integration capacity

- Series application to meet cost constraints

- Greatest possible flexibility based on preload, runnability and diameter ranges

- Bearing elements of the LEL type consist of two inner and two outer raceways, along with a plastic cage with retained balls. The race rings are divided at one point to compensate for the temperature expansion factor. They possess compensatory properties for demanding forms of stress. LEL are generally mounted free from clearance. The preload can be defined individually to meet the specific requirement. See ‘Technical information’ for the adjustment methods.

Diameter Range

- Infinitely variable from 70 to 2000 mm

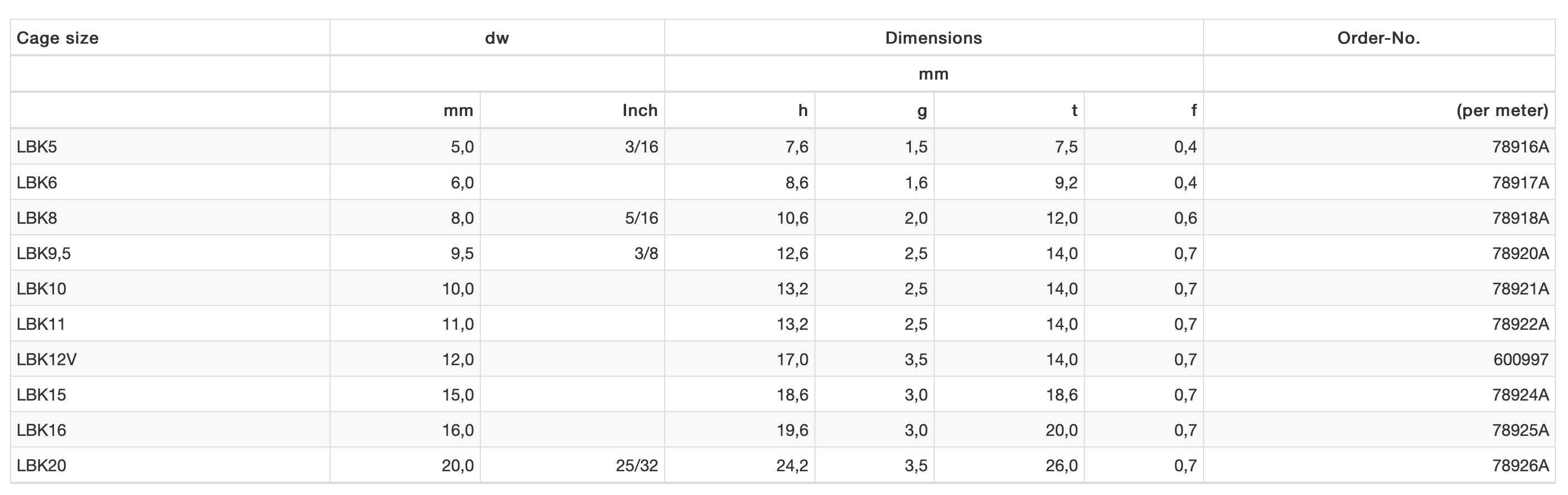

Mating structure

The bearing element mounted determines the overall construction’s load bearing capacity. Hence the mating construction can be made of alternative materials such as steel, aluminium or plastic. Axial and radial accuracy are defined to a substantial extent by the mating components. These properties can be enhanced by boosting the accuracy of manufacture.

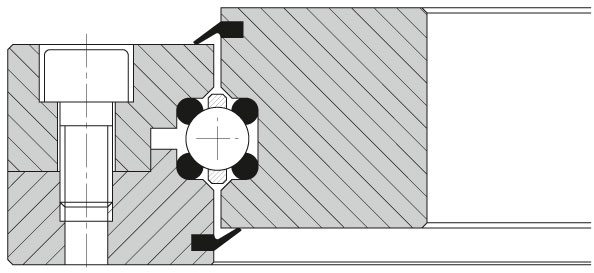

Constructive Example

Technical Details

| Material | Ball race rings: 54SiCr6, rolling element: 100Cr6, cage: PA12 |

|---|---|

| Temperature in use | –30 °C to +80 °C, briefly up to +100 °C |

| Circumferential speed | max. 5 m/s, without seals max. 10 m/s |

| Lubricant grease | Klüber Isoflex Topas NCA52 |

| Lubricant schedule | See ‘Technical information’ |

| Tolerance details | See ‘Technical information’ |

Please find additional information on bearing selection, calculation, mounting and setting in‘Technical information’.

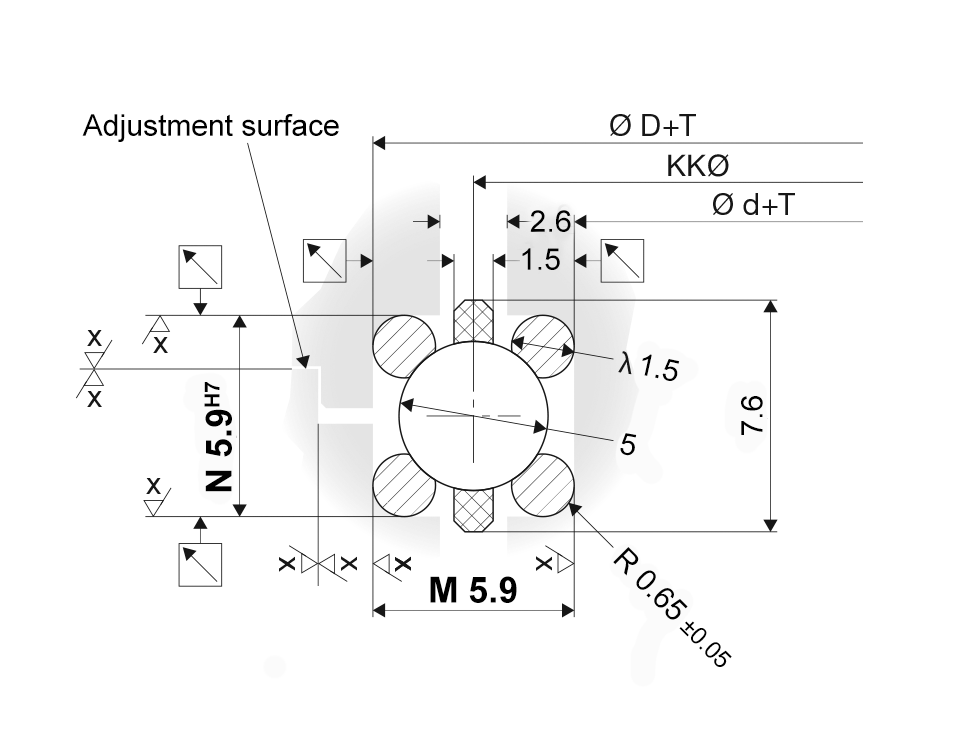

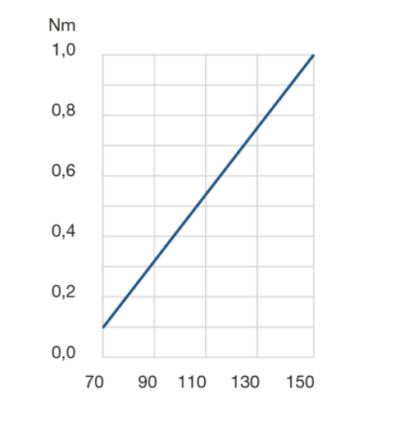

LEL 1.5 (70-150) Drawing

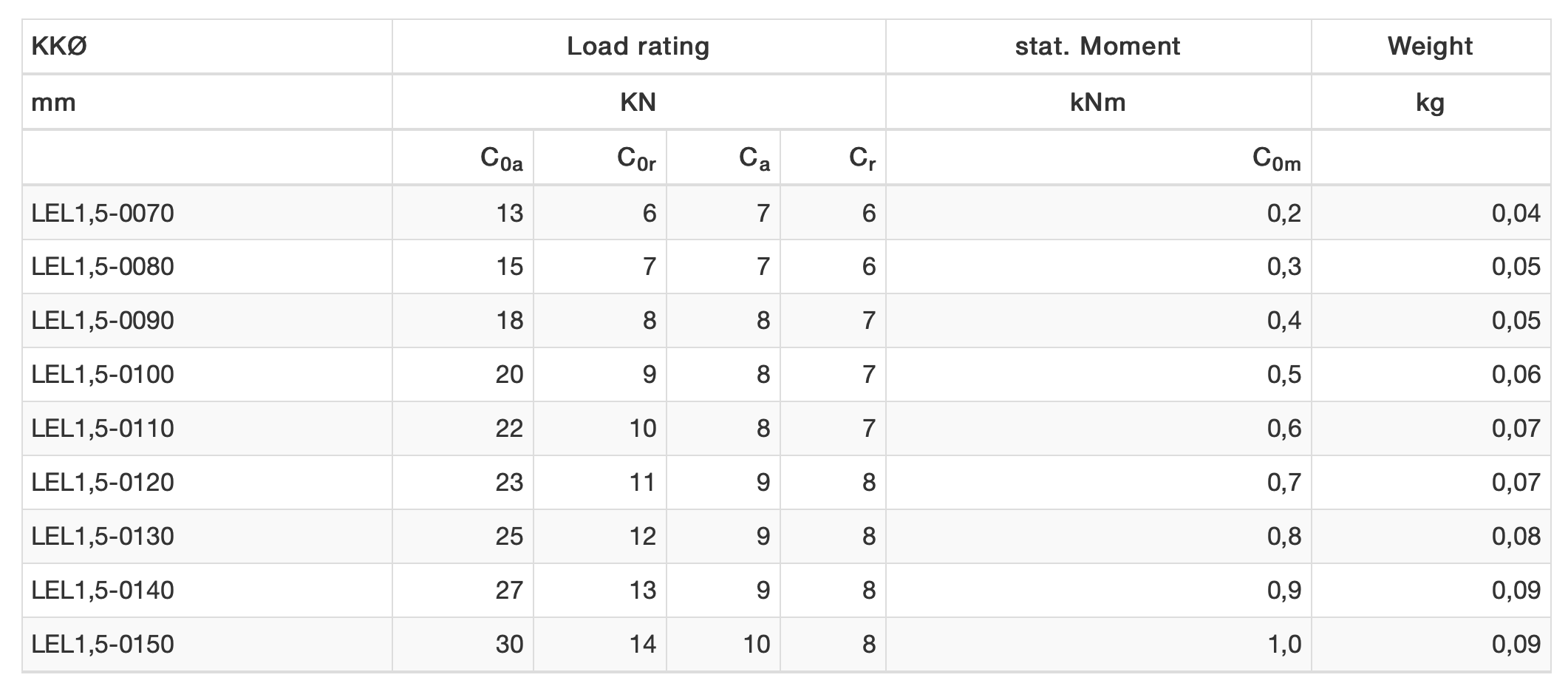

Loadings

Rotational resistance

The rotational resistance indicates the preload on the bearing assembly. It is dependent on the respective type and the race ring diameter. The values indicated in the diagram are standard values and can be aligned individually.

Radial and axial runout accuracy

The running accuracies indicated in the diagram are maximum values and may be improved by restricting the tolerances.

Please find additional information on bearing selection, calculation, mounting and setting in‘Technical information’.

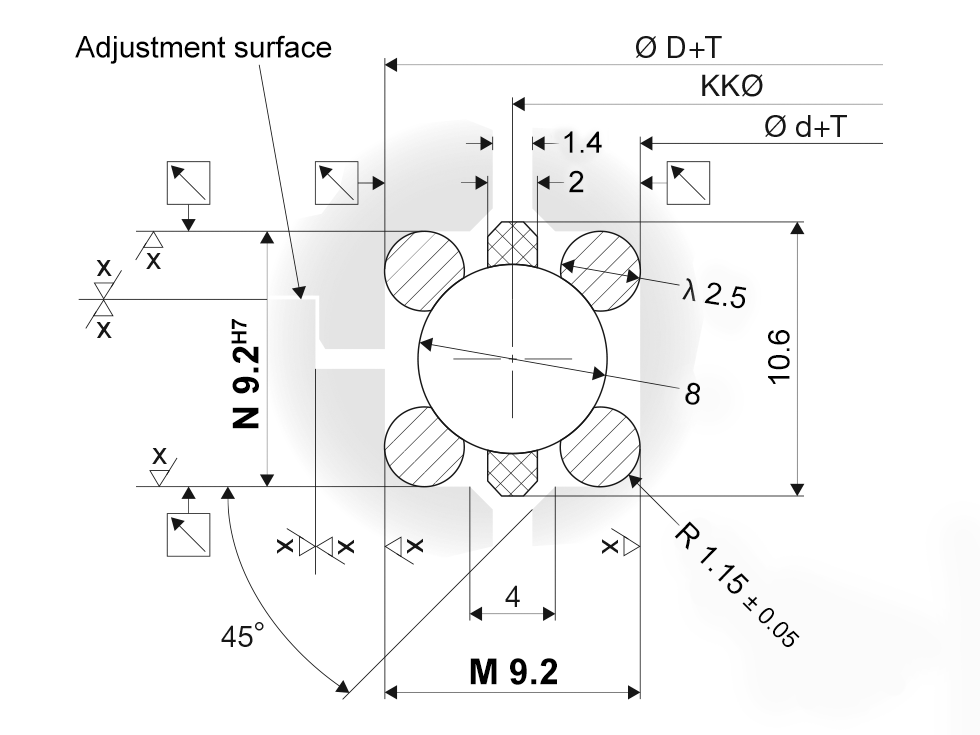

LEL 2.5 (150-300) Drawing

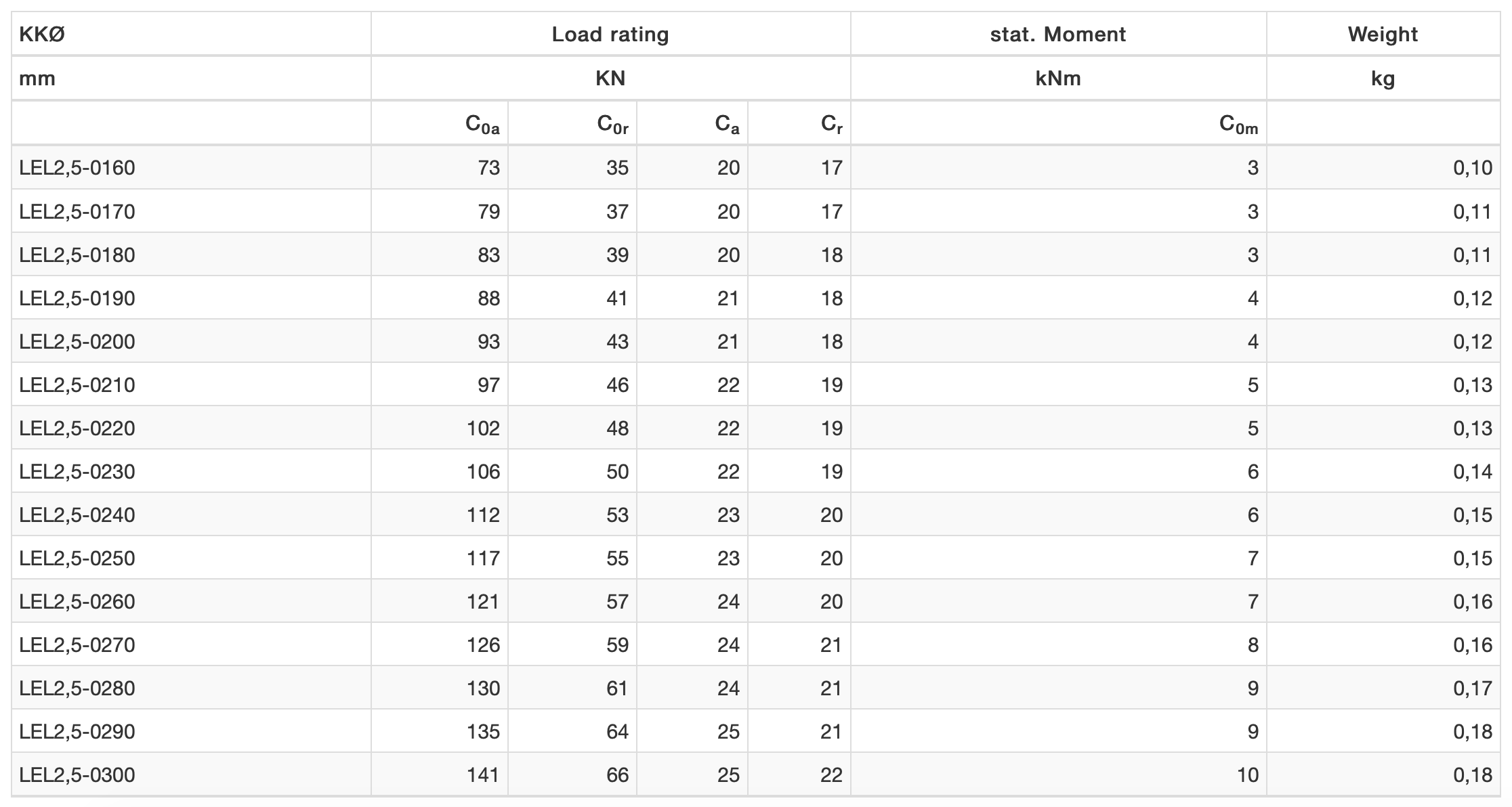

Loadings

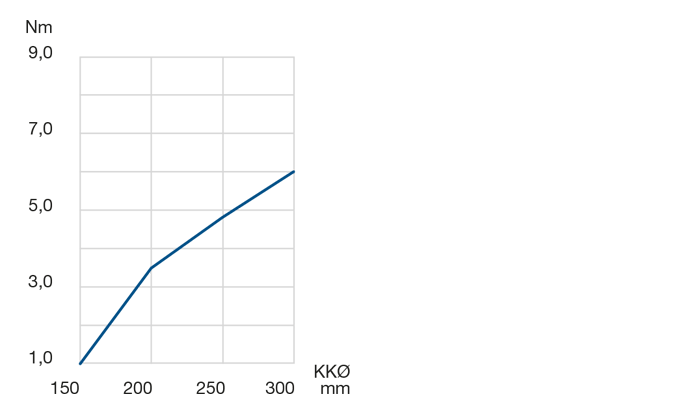

Rotational resistance

The rotational resistance indicates the preload on the bearing assembly. It is dependent on the respective type and the race ring diameter. The values indicated in the diagram are standard values and can be aligned individually.

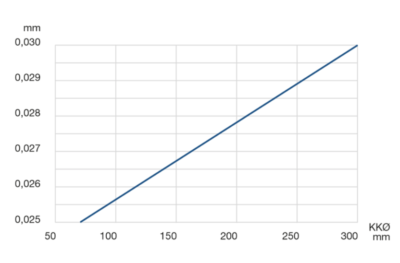

Radial and axial runout accuracy

The running accuracies indicated in the diagram are maximum values and may be improved by restricting the tolerances.

Please find additional information on bearing selection, calculation, mounting and setting in‘Technical information’.

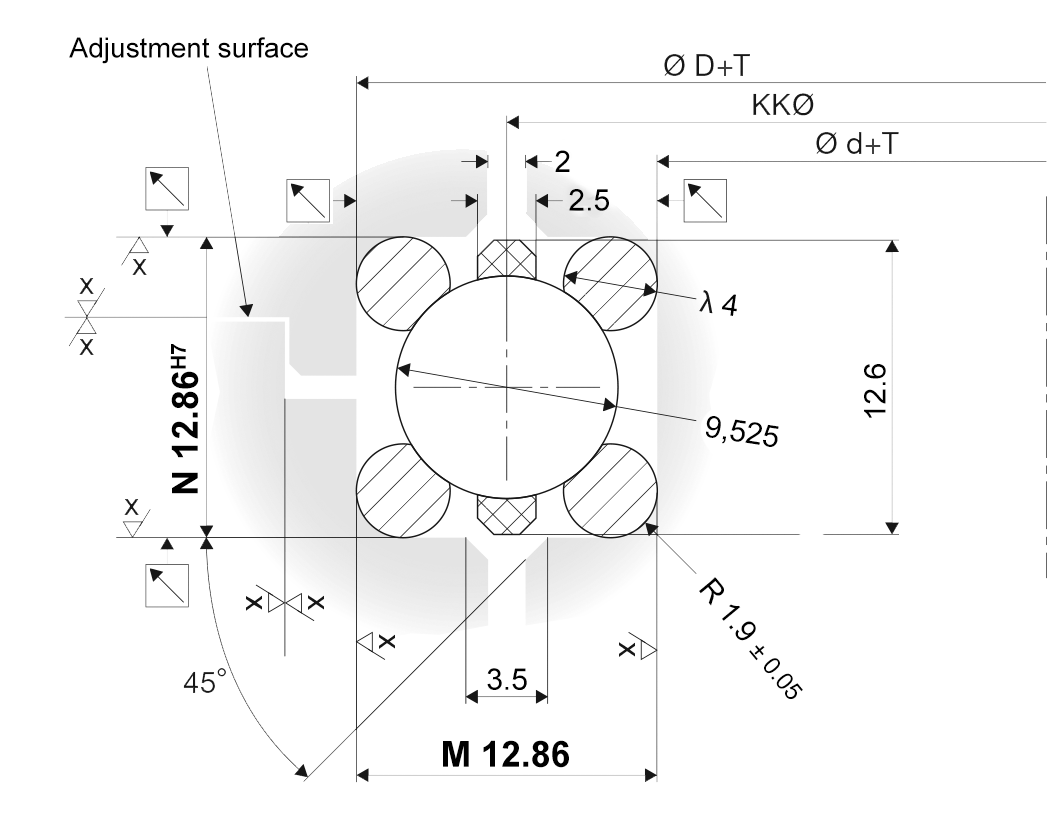

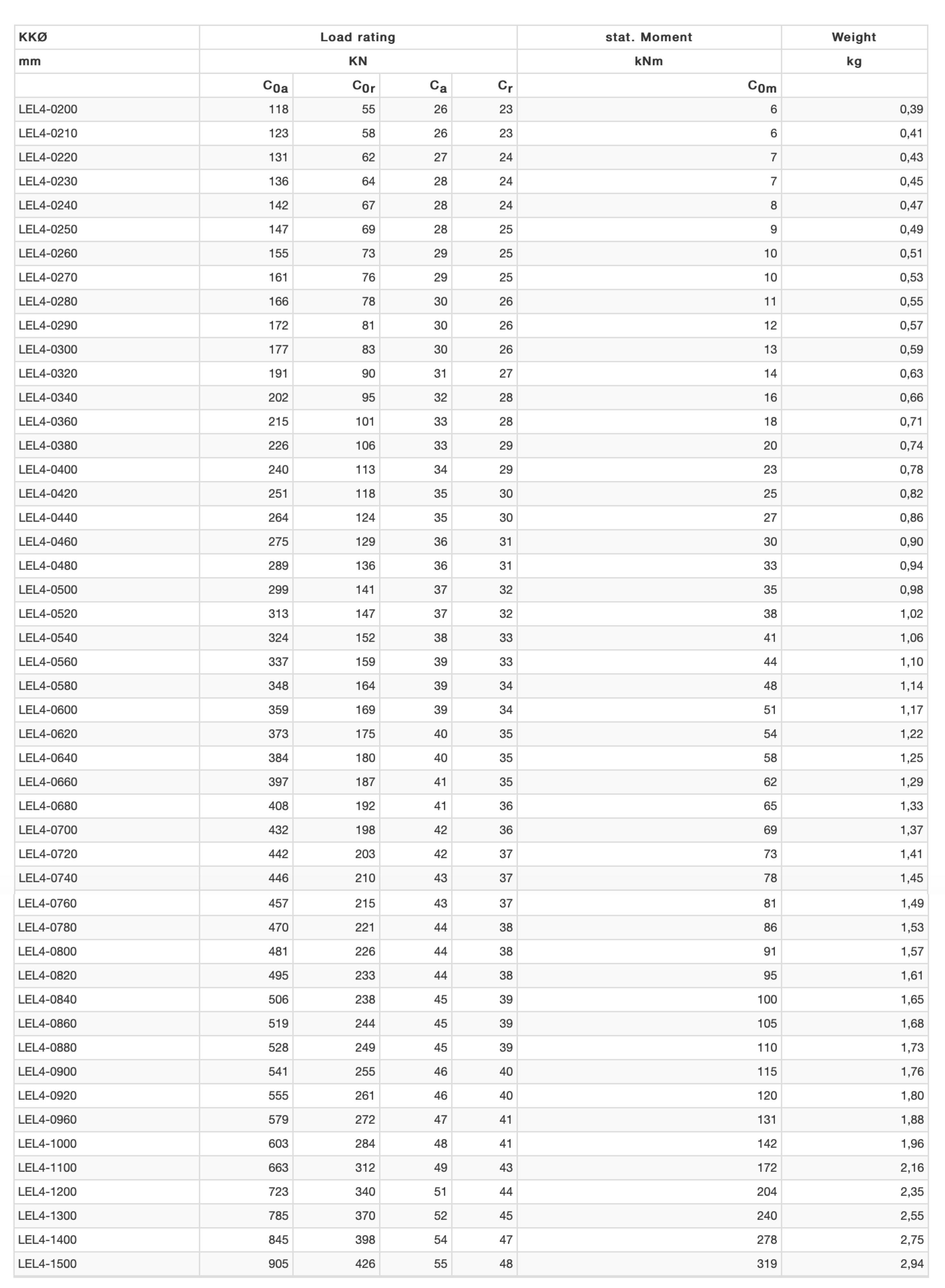

LEL 4 (220-1500) Drawing

Loadings

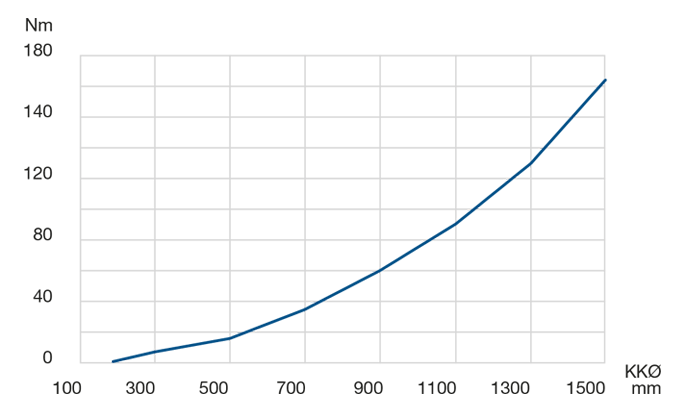

Rotational resistance

The rotational resistance indicates the preload on the bearing assembly. It is dependent on the respective type and the race ring diameter. The values indicated in the diagram are standard values and can be aligned individually.

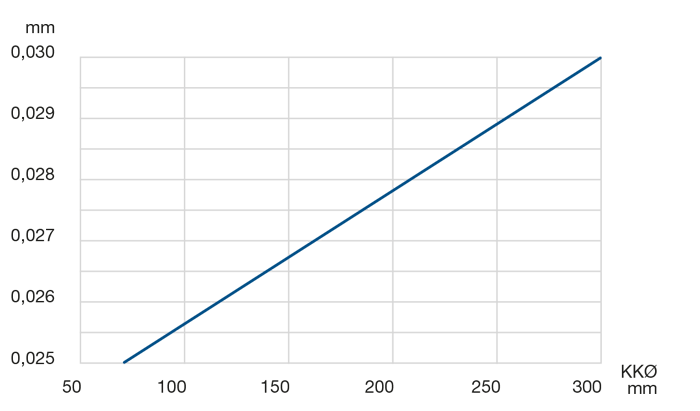

Radial and axial runout accuracy

The running accuracies indicated in the diagram are maximum values and may be improved by restricting the tolerances.

Please find additional information on bearing selection, calculation, mounting and setting in‘Technical information’.

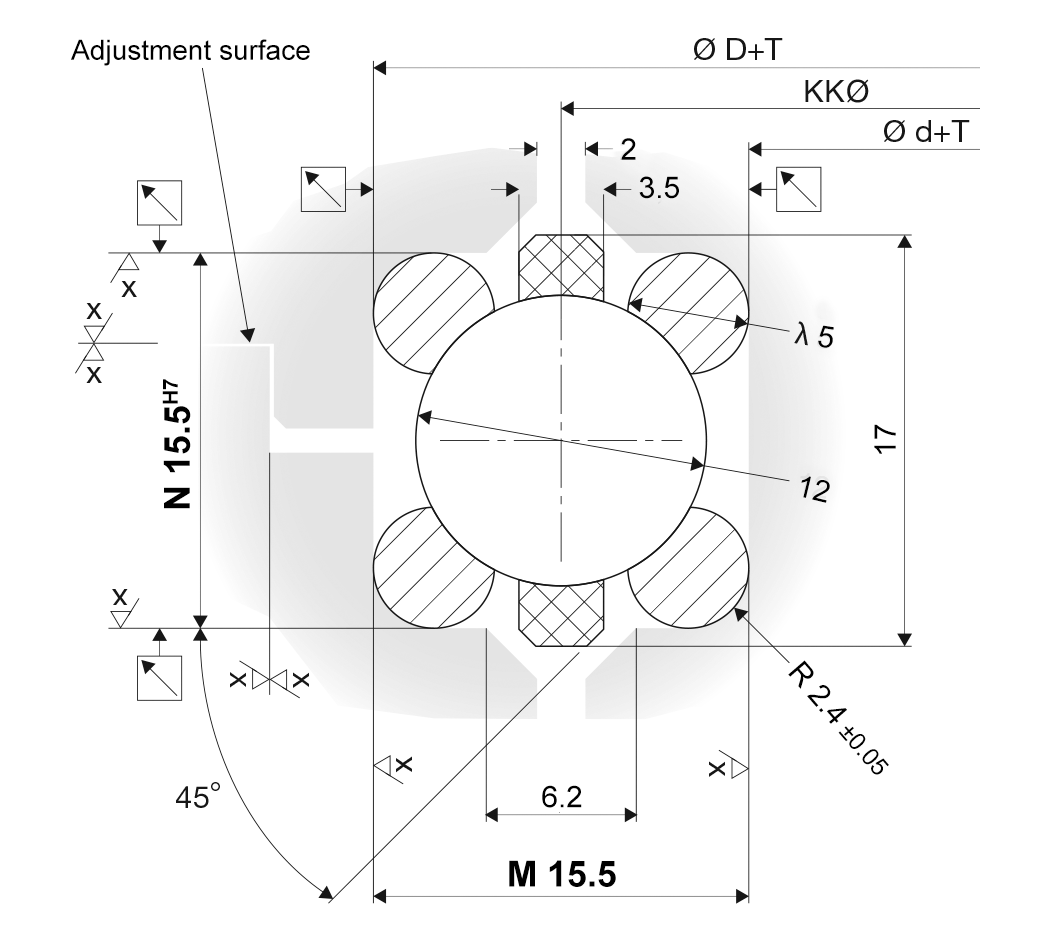

LEL 5 (220-1500) Drawing

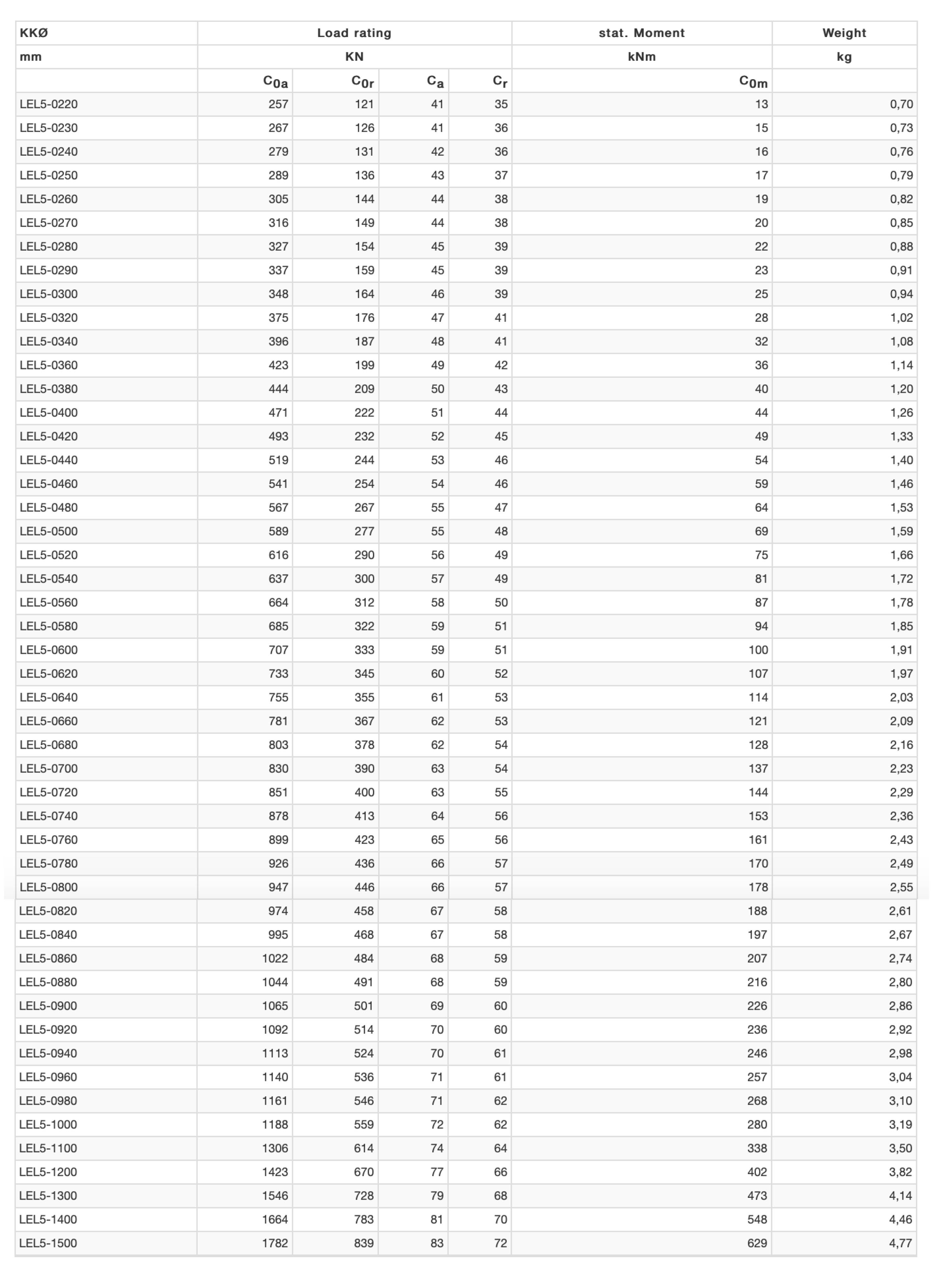

Loadings

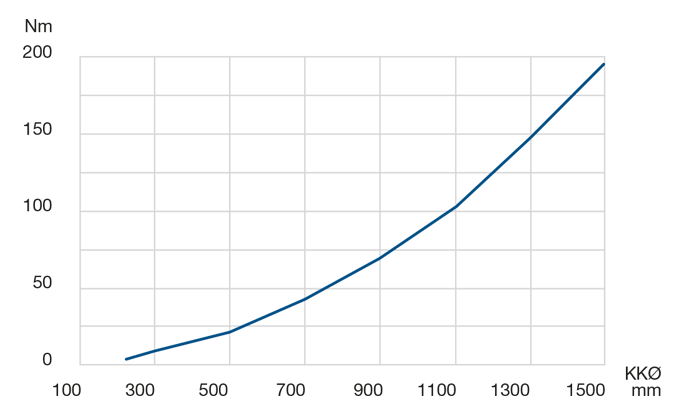

Rotational resistance

The rotational resistance indicates the preload on the bearing assembly. It is dependent on the respective type and the race ring diameter. The values indicated in the diagram are standard values and can be aligned individually.

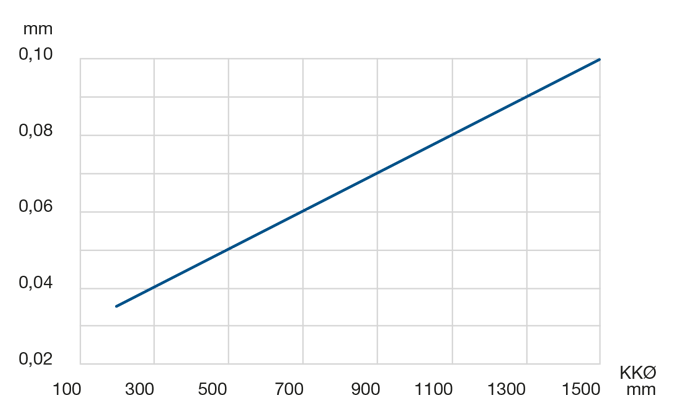

Radial and axial runout accuracy

The running accuracies indicated in the diagram are maximum values and may be improved by restricting the tolerances.

Please find additional information on bearing selection, calculation, mounting and setting in‘Technical information’.

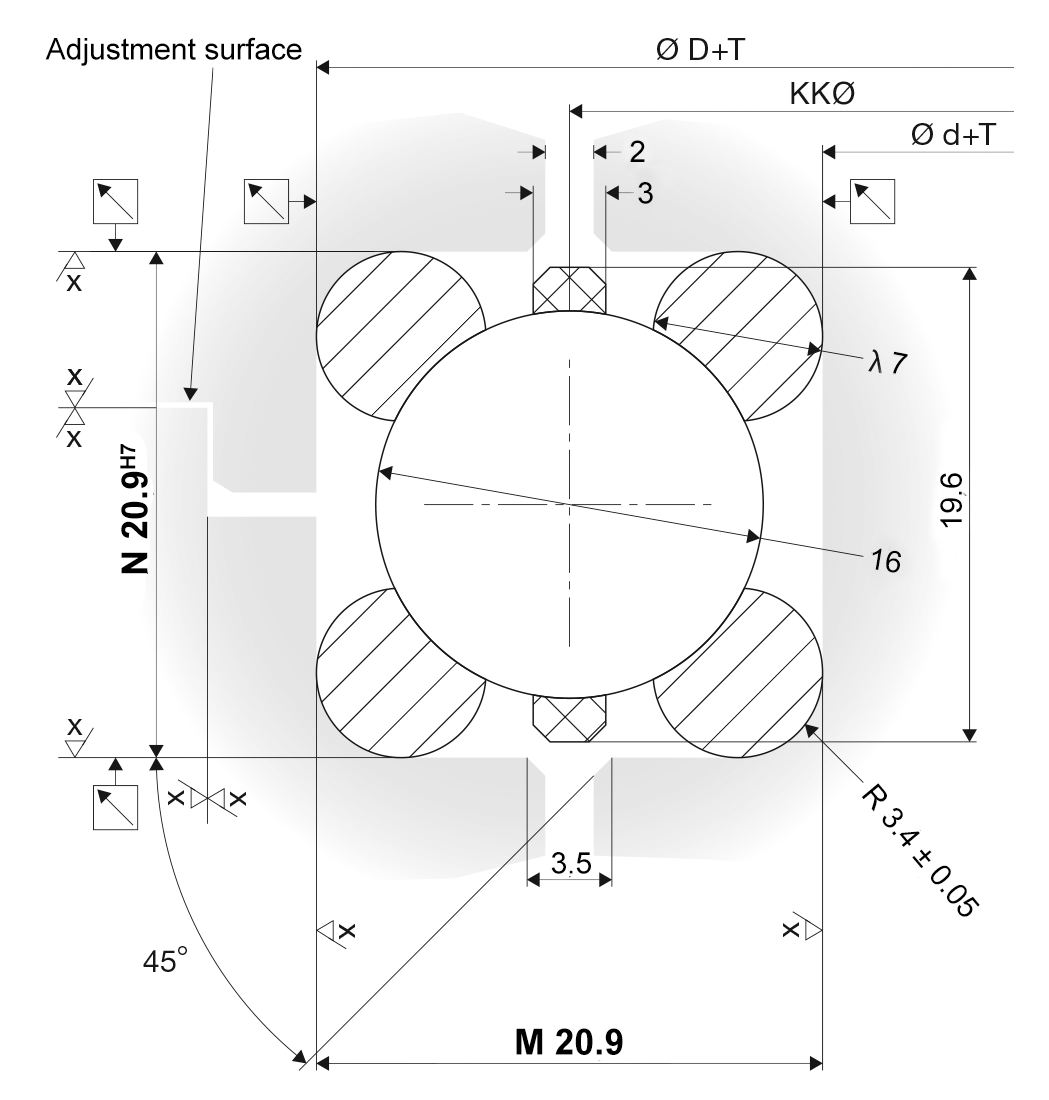

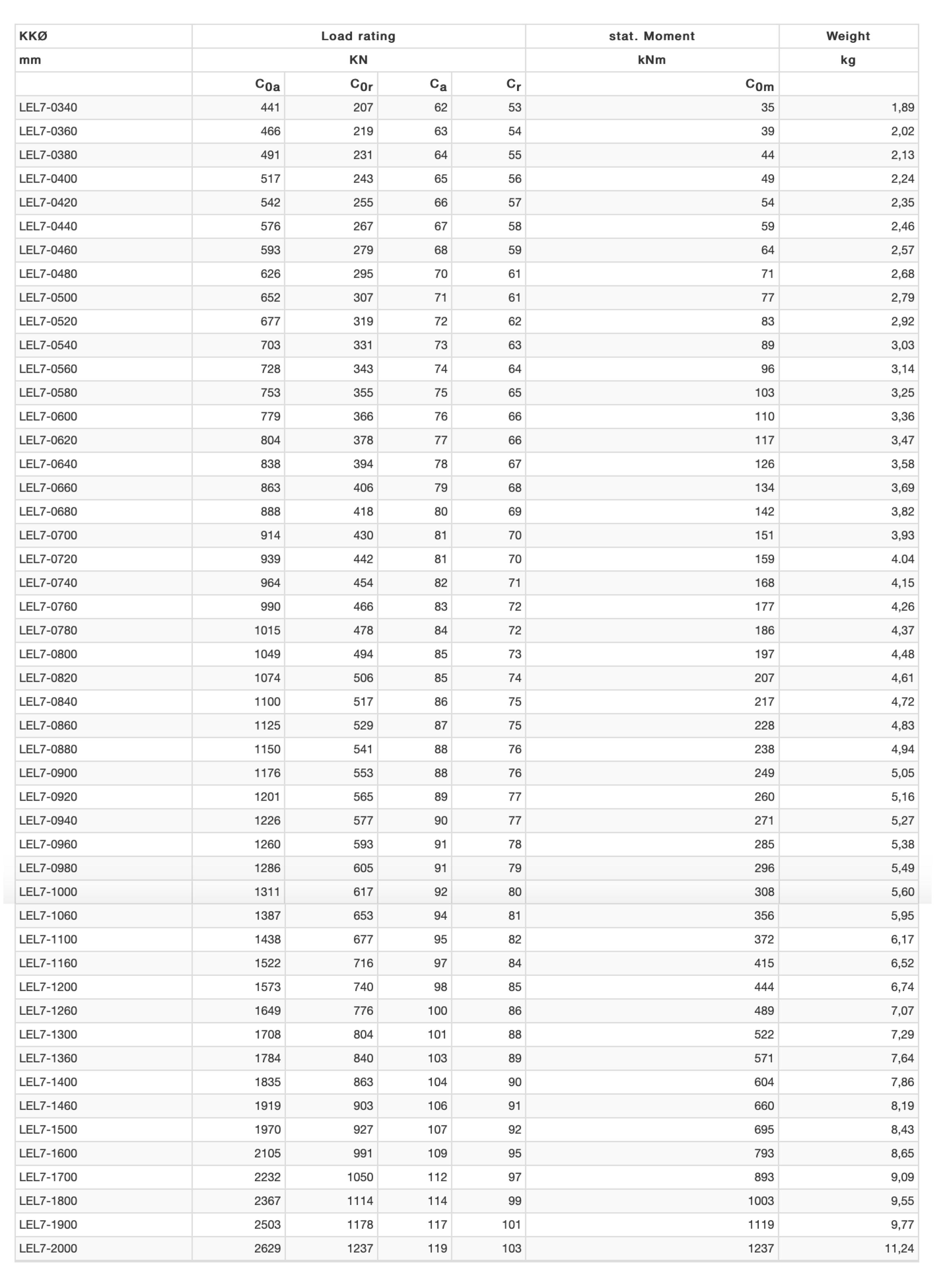

LEL 7 (340-2000) Drawing

Loadings

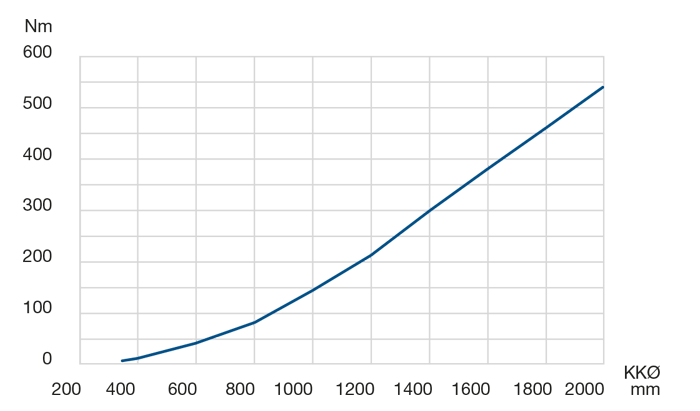

Rotational resistance

The rotational resistance indicates the preload on the bearing assembly. It is dependent on the respective type and the race ring diameter. The values indicated in the diagram are standard values and can be aligned individually.

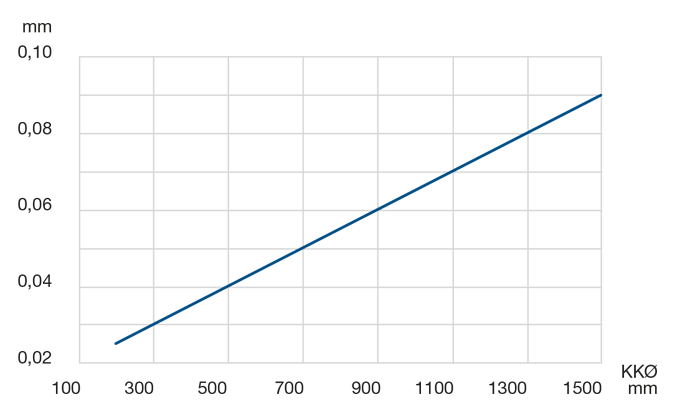

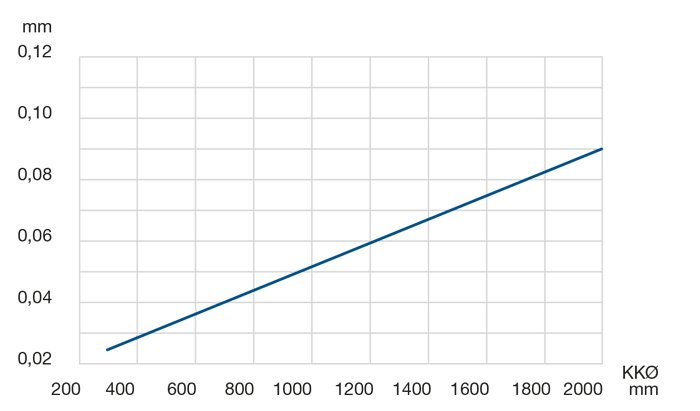

Radial and axial runout accuracy

The running accuracies indicated in the diagram are maximum values and may be improved by restricting the tolerances.

Please find additional information on bearing selection, calculation, mounting and setting in‘Technical information’.

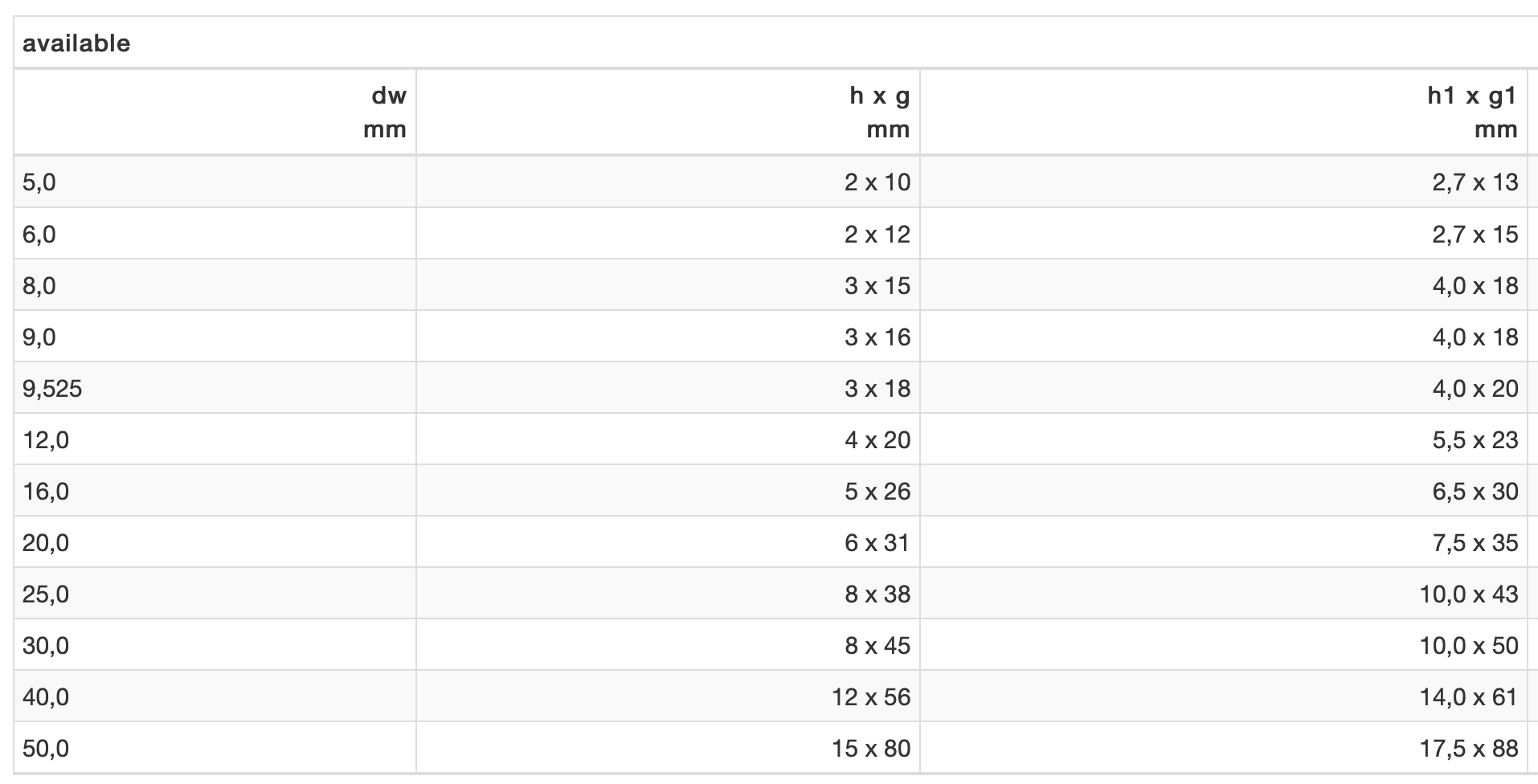

Standard Cages

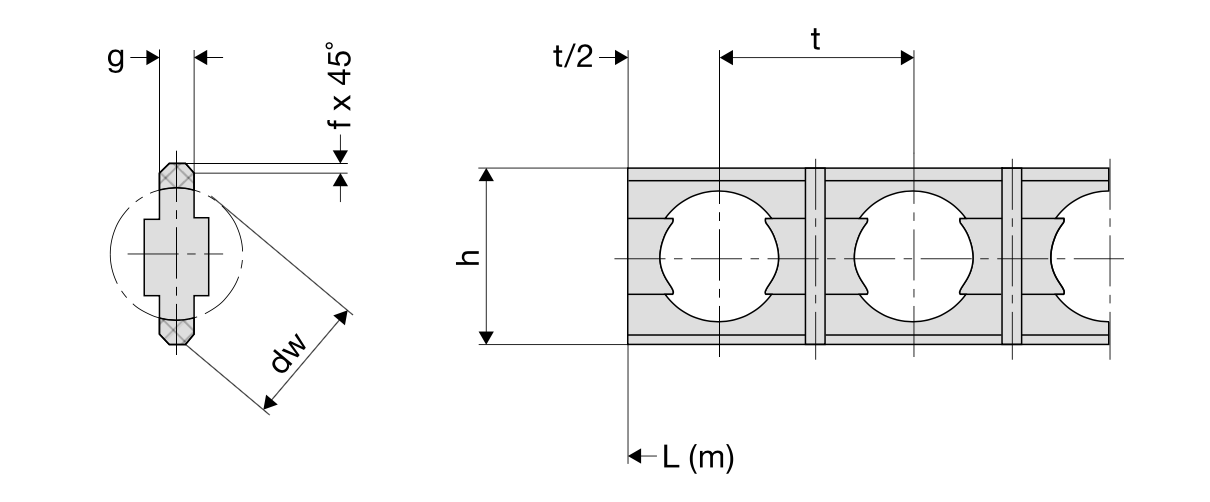

Strip cages for the LBK series

The band cage is segmented in the length required respectively and delivered fitted with balls and ready-to-use. The number of segments is dependent on the bearing diameter and the ball size. The band cage can also be created in one part for special applications.

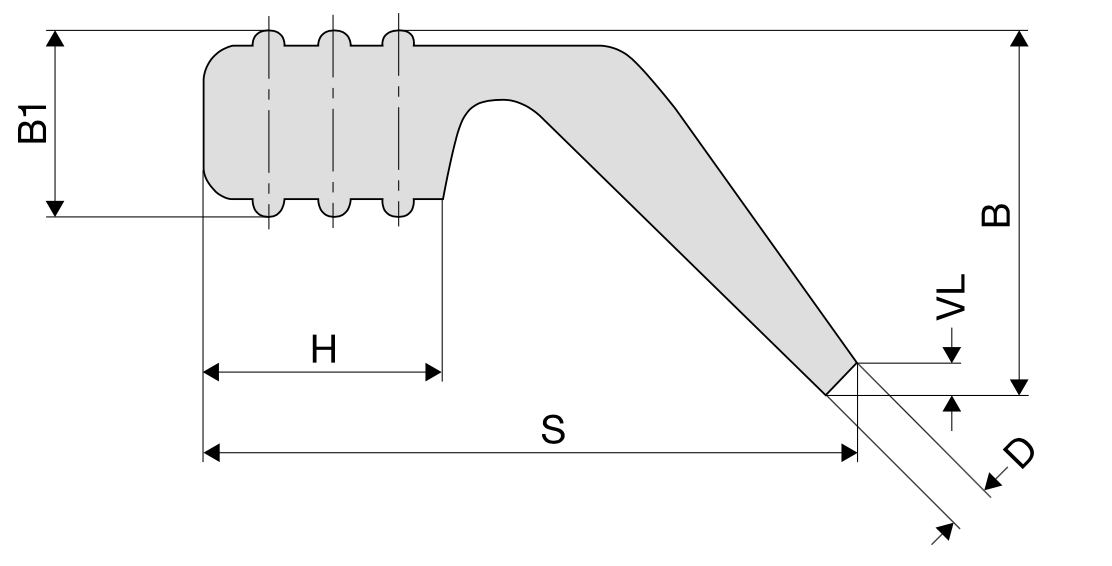

Special Cages

Flat cages made of hard fabric, non-corrosive steel, brass.

It is mandatory to use a flat cage for temperatures exceeding 100 °C and with ball diameters larger than 20 mm. Special solutions, including complete non-corrosive properties or radiation resistance, are also possible.

Special cages in the form of band or prong-type cages are available for special requirements in terms of ambient conditions or mounting space.

Franke also delivers materials such as plastic, non-corrosive, brass and Teflon.

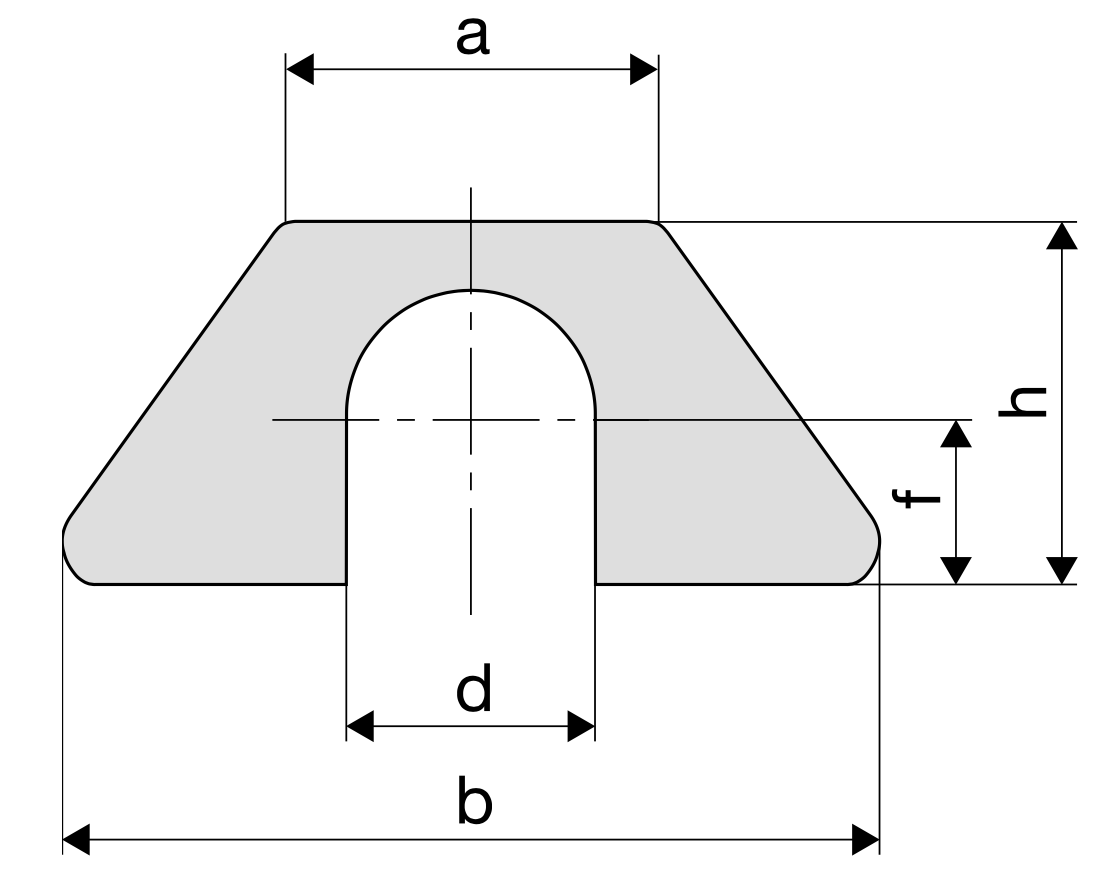

Washers

Larger bearings and bearing elements use washers to simplify adjustment between the separate inner and outer rings. The washers are made of non-corrosive sheet steel. It is sensible to include in the design specifications a theoretical initial gap of 0.5 mm for the adjustment.

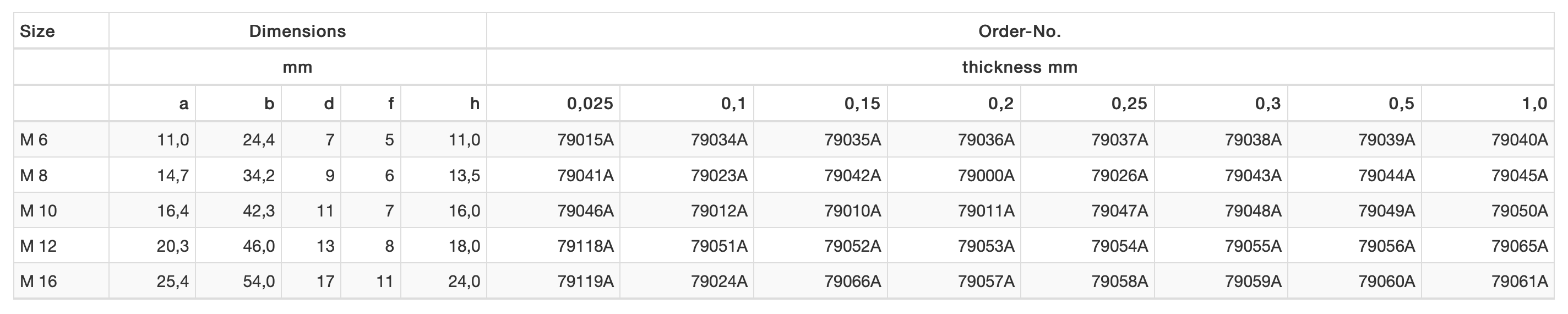

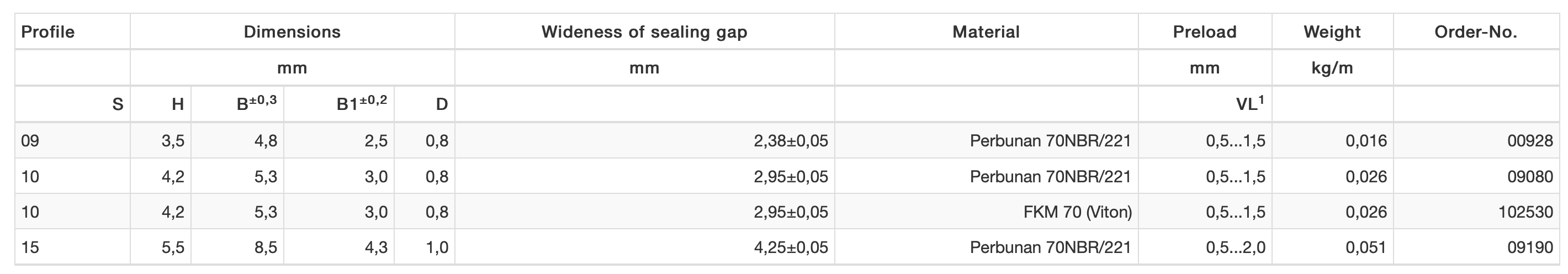

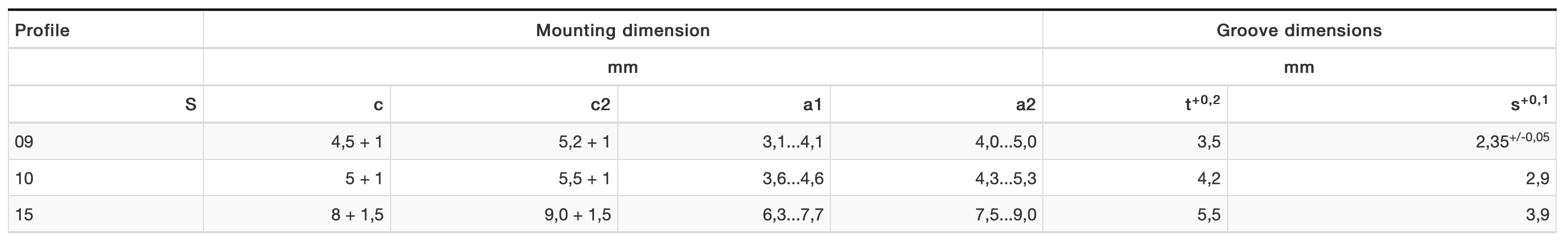

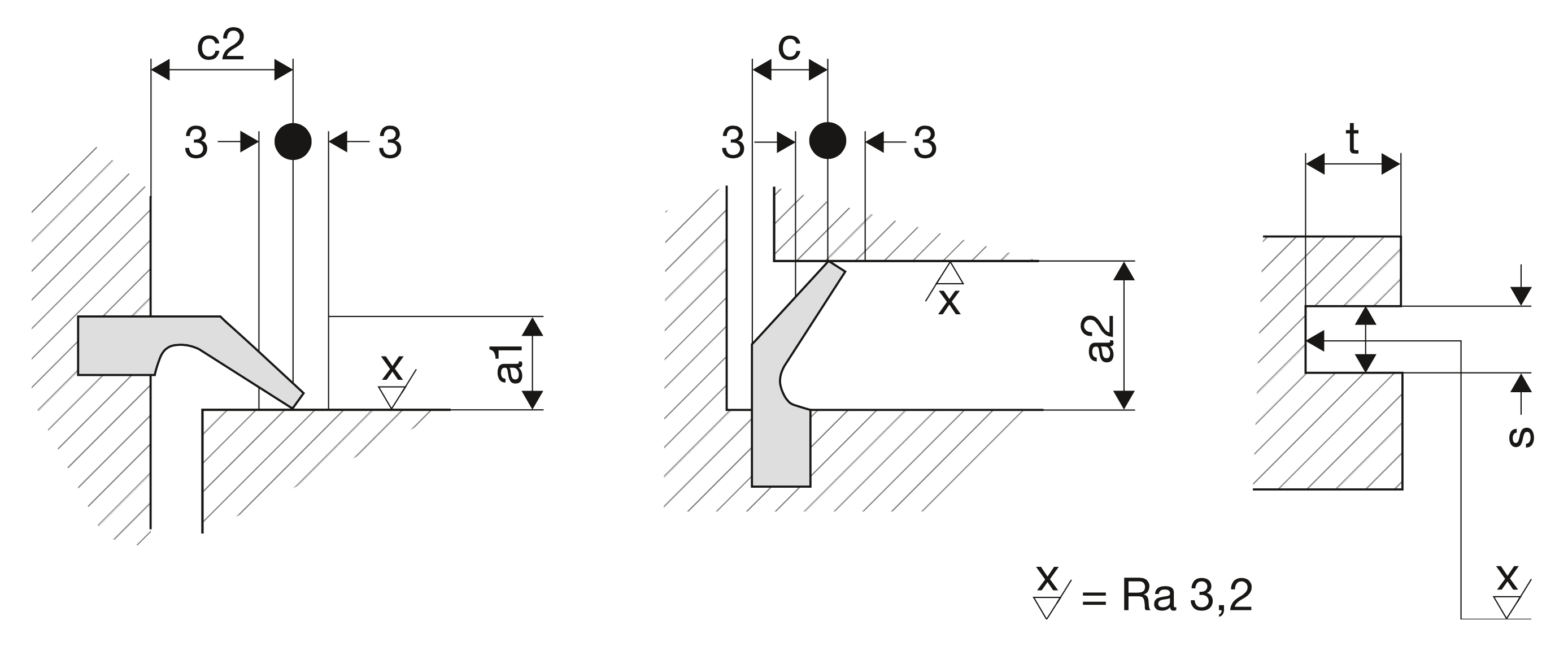

Seals

By standard, the bearing assemblies are fitted with sleeve seals S120. Temperature: –30 °C to +80 °C (NBR).

Max. circumferential speed: 5 m/s.

The seals can be ordered by the meter in order to seal the construction (e.g. when using a bearing element). The joint is then bonded using adhesive agent Loctite 401®.

Call us for more information on 01772 780200

Advantages

Maximum design freedom, without compromising precision or load capacity.

Principle

4 Point ContactFreedom of Design

4 Point contact principle to take load from all directions. the rolling process does not take place directly between the rolling elements and the mating structure, but rather on special race rings, giving maximum freedom of design.

Compact

Minimal Mounting SpaceMinimal Mounting Space

Requiring only a small mounting space, the compact and highly resilient four-point geometry of Franke Bearings gives you maximum freedom of design, making an ideal design component for your application.

Material

Unlimited Material ChoiceUnlimited Material Choice

Franke lightweight aluminum bearings are 65% lighter than steel, offering substantial design freedom. Available in a wide range of materials, from aluminium, bronze ceramic, plastic, carbon, 3D printed and many more.

Bespoke

Built To Your ApplicationBuilt To Your Application

Available in sizes from 60 – 2000+ mm. 95% of our products are bespoke versions. Franke rotary solutions are always designed and built to fit your application. We work with you from concept, to prototype through to final testing.