Franke Bespoke Slewing Rings for AGV’s

New autonomous electric transport systems are making logistics more dynamic. Franke offers the ideal rolling bearings for such innovative applications. With the compact and highly customisable Franke wire race bearings, designers have the greatest possible freedom for their product ideas. Robust and capable of bearing loads on all sides, wire race bearings also guarantee a very long service life without the need for maintenance. Typical applications for Franke Wire Race Bearings in electric vehicles are in the drive or steering systems.

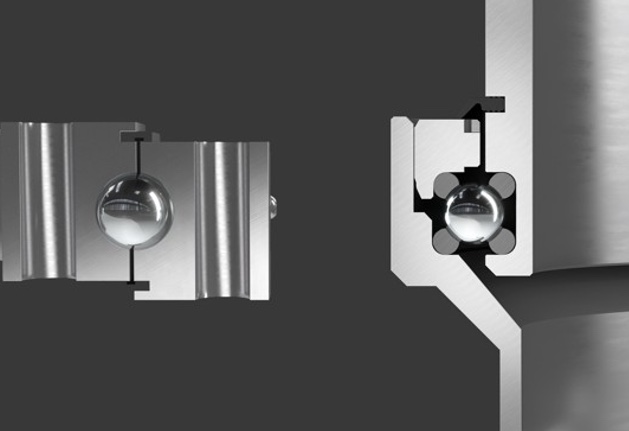

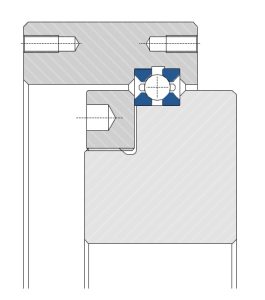

The decisive difference between a conventional ball bearing and a Franke wire race bearing lies in the race rings. In a wire race bearing, the rolling elements do not roll directly on the solid housing rings, but on hardened wire rings inserted there.

The flexibility of this principle makes it possible to design more freely and simply in order to develop better products. Thanks to their patented technology, Franke wire race bearings offer maximum design freedom without compromising on load-bearing capacity. The enclosing construction can be realised in a variety of lightweight materials and its geometry can be optimally adapted to the respective application.

The new LER1.5 series was developed specifically for use in ultra-compact applications such as HRC robots or medical devices. With its installation space of just 5×6 mm, the new LER 1.5 more than meets the trend towards miniaturisation in the handling and automation sector.

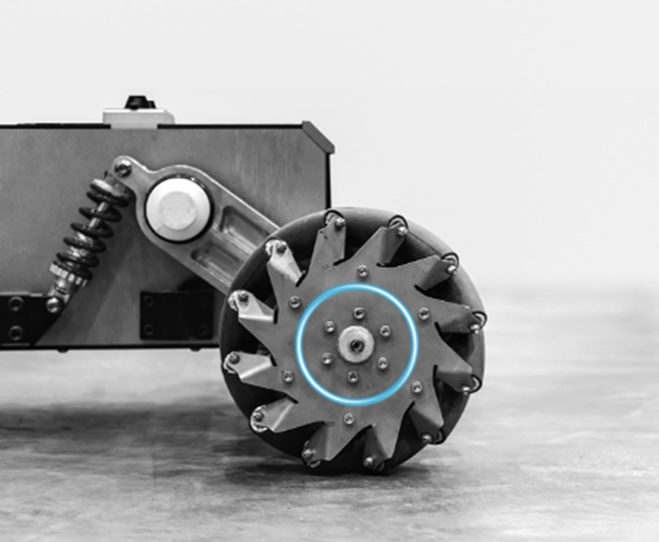

Getting logistics rolling: Wire race bearings in AGVs

Very compact, simple bearing arrangements are used for the Mecanum wheels of an omnidirectional AGV. High rigidity is a basic requirement for absorbing the reciprocating forces. Furthermore, high tilting moments must be taken into account with eccentric loads. In addition, AGVs are very flat and compact. This means that the installation space for components in the chassis and drive areas is very limited.

The compact and rigid rectangular profile of the wire race bearings used means that the load requirements can be fully met. Double bearings are often used to optimise load absorption.

This compact bearing element can be easily integrated into existing wheel designs. The outer and inner diameters remain unaffected. The open races and a one-piece plastic ribbon cage with retained rolling elements simplify the installation of the bearing in the housing parts.

The bearing rings with rectangular profile can be inserted directly into the housing parts and do not require any extensive machining of the bearing bed. The space-saving design also means that an internal lip seal can be accommodated. This modular system has already become established in several AGVs. In some cases, direct drives integrated into the housing can be combined with the wire race bearings to create a complete drive and bearing assembly.

Conclusion

Digital transformation, increasing variant diversity and flexible batch sizes place high demands on logistics and production. Driverless transport systems are helping to meet these requirements. They will continue to gain in importance in the future and become increasingly autonomous.

Franke wire race bearings and thin section bearings are the perfect solution for supporting wheel hubs or swing axles in vehicles with limited installation space. They impress with

- Compact dimensions

- low weight

- smooth running with adjustable preload.